NordSpace Advances High Scale Additive Manufacturing for Medium-Lift Rocket Engines via Canada-Germany R&D Collaboration

A critical step toward NordSpace’s ongoing R&D efforts to advance orbital launch vehicles that are fully scalable from light to medium-lift payload capacities

Canada’s growing demand for responsive medium-lift space launch requires continuous investment in disruptive manufacturing technologies that shorten timelines, boost reliability, and reduce costs”

MARKHAM, ONTARIO, CANADA, January 22, 2026 /EINPresswire.com/ -- NordSpace Corp. is pleased to announce that it is receiving advisory services and up to $335,000 in funding from the National Research Council of Canada Industrial Research Assistance Program (NRC IRAP) to support a research and development project that will advance its large format multi-material additive manufacturing capabilities for medium-lift rocket engines. This project will involve a major Canada-Germany R&D collaboration between NordSpace, the Fraunhofer Institute for Laser Technology, and SWMS (Systemtechnik Ingenieurgesellschaft mbH). This milestone builds upon NordSpace’s recent launch of its Advanced Manufacturing for Aerospace Lab (AMA Lab), marking an important step toward NordSpace’s ongoing research and development efforts to advance orbital launch vehicles that are fully scalable from light to medium-lift payload capacities. NordSpace's Tundra and Tundra+ light lift vehicles, capable of 500 kg and 1,100 kg to LEO respectively, are being designed specifically to scale to the medium lift Titan (5,000 kg+ to LEO) by the early 2030s.— Rahul Goel, CEO

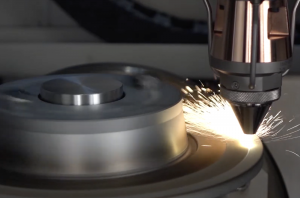

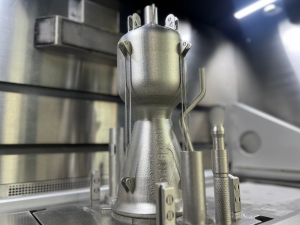

This advanced manufacturing project for space propulsion harnesses breakthrough methods such as large volume, high-speed, high-resolution, multi-metal deposition to optimize rocket engine design, fabrication, and testing. NordSpace will partner with Fraunhofer ILT – the German research institute that has developed the world-leading EHLA laser-based high-speed additive manufacturing capability, and SWMS – the German company that has developed the CAESA software for AI-powered advanced manufacturing path planning optimization. This collaborative project will support NordSpace in developing next-generation, large-scale, regeneratively cooled liquid engines, validated through rigorous hot-fire test campaigns and positioned for flight qualification and commercial scale-up.

“Canada’s growing demand for responsive and cost-effective medium-lift space launch requires continuous investment in disruptive manufacturing technologies that shorten development cycles, boost reliability, and reduce production costs,” said Rahul Goel, CEO and Founder of NordSpace. “This project represents a crucial step for NordSpace to work with world-leading technology partners in Germany to bring additive manufacturing breakthroughs that will directly benefit Canada’s industrial base, making our factories and labs more competitive and efficient while accelerating the time to market for our medium-lift Hadfield and Garneau engine lines.”

This announcement builds on NordSpace’s Advanced Manufacturing for Aerospace Lab launched earlier this year with Ontario Centre for Innovation support and another advanced manufacturing project that received funding from the Canadian Space Agency. The AMA Lab has already accelerated the design of NordSpace’s 3D-printed Hadfield engines and enhanced development cycles through AI-driven design methodologies and direct validation at the company’s test range. Now, this new Canada-Germany collaborative R&D project will go further into efficient production methods for these advanced rocket engines.

For more information on NordSpace’s AMA Lab or to explore partnership opportunities, visit www.nordspace.com or contact contact@nordspace.com. NordSpace will also present updates on this initiative at the Canadian Space Launch Conference on May 5, 2026 in Ottawa.

About NordSpace

NordSpace, a 100% Canadian-owned aerospace defence company established in 2022, develops vertically integrated solutions for responsive orbital launch vehicles, spaceports, turn-key satellites, and mission-critical software systems. 100% designed, built, and flown in Canada to go from anywhere on Earth to anywhere in space. The company’s mission is to advance life on Earth through space, delivering innovation, jobs, national security, and sovereignty.

Media Inquiries:

Team NordSpace, NordSpace Corp., contact@nordspace.com

Website: https://www.nordspace.com/

About Fraunhofer ILT

Fraunhofer Institute for Laser Technology ILT is one of the world’s pioneering centers for laser-based metal additive manufacturing, with a track record that stretches back to the mid-1990s. At that time, ILT researchers filed the foundational patent for what is now known as Laser Powder Bed Fusion (LPBF), originally introduced as Selective Laser Melting, laying a cornerstone for modern industrial metal 3D printing. Building on more than 25 years of experience in LPBF and laser material deposition processes, Fraunhofer ILT continues to drive innovation across the entire process chain, from beam source and optics development to machine technology and industrial integration, making it a globally recognized driver of laser-based additive manufacturing for aerospace, turbomachinery, automotive and medical applications.

Website: https://www.ilt.fraunhofer.de/en.html

About SWMS

SWMS Systemtechnik Ingenieurgesellschaft mbH, founded in 1996 and based in Oldenburg, Germany, is an engineering company specializing in innovative software and consulting solutions for digital product development and production. With a focus on high-tech industries such as aerospace, automotive, shipbuilding, and wind energy, SWMS develops manufacturer-independent applications in its CAESA solutions portfolio for tasks including CAD/CAM process automation, additive manufacturing, and automated fiber placement. By combining engineering know-how with customized software development, SWMS supports customers in implementing efficient, future-proof production processes and end-to-end digital workflows.

Website: https://www.swms.de/en/

Team NordSpace

NordSpace Corp.

contact@nordspace.com

Visit us on social media:

LinkedIn

Instagram

YouTube

X

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.